There is no doubt that demand for ethical and natural material is outstripping supply.

Subscribe now for unlimited access to all our agricultural news

across the nation

or signup to continue reading

Radical transparency is also in demand. Products that carry hallmarks of quality and provenance, are highly sought-after.

This is creating niche opportunities for innovative startups such as Full Circle Fibres, which is transforming cotton bolls from St George paddocks into fabrics of known origin.

After decades of complicit acceptance of the proliferation of cheap and ever-changing options, wearers have been shocked by recent revelations about how clothes are made and what from.

The 2013 Rana Plaza factory collapse in Bangladesh exposed exploitative working conditions which sadly continue to this day, despite the best efforts of many groups wanting workers to be paid a living wage and have safe work environments.

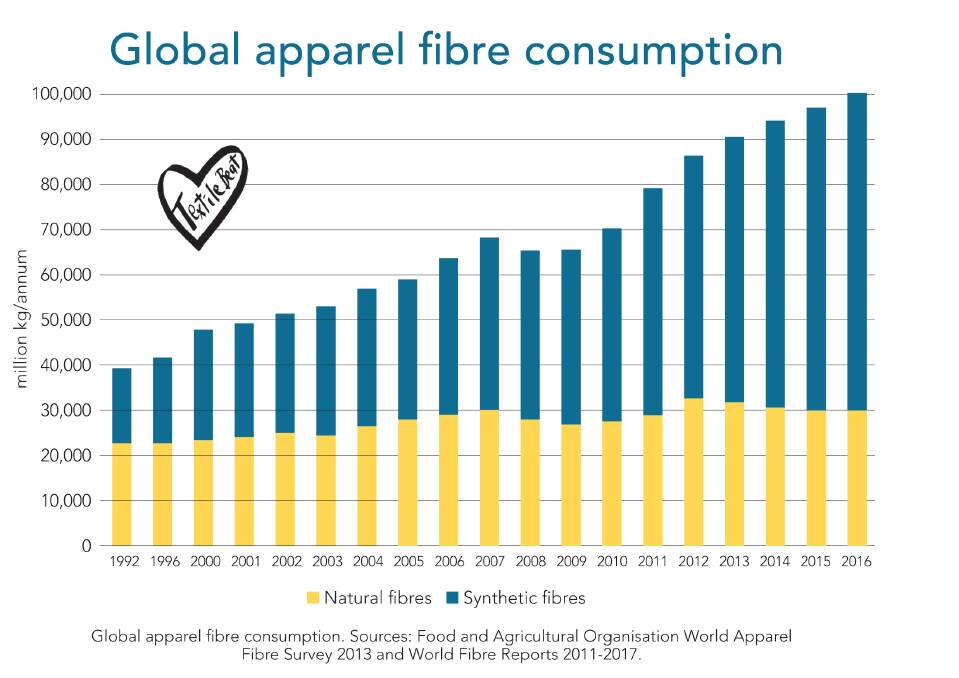

There's also the issue of toxic dyes and dirty processes, and the fact that two-thirds of new clothing is made from synthetic fibres - derived from fossil fuels - known to be shedding microplastic particles into the air, homes, waterways and oceans and now found in our food, drinking water and salt.

The main alternative to synthetics is cotton, which is itself not without controversy. Australian growers produce high-quality sustainable cotton and have developed on-farm management practices that minimise pesticide and water usage.

Yet they are still plagued by allegations of water-theft and images of fish kills in the Murray Darling system.

As awareness of the climate emergency continues to build, many conscientious consumers are looking for beautiful ecologically-sound quality local products that are produced with integrity, traceability and authenticity.

Through her unique set of qualifications and skills, Meriel Chamberlin had a vision to develop Full Circle Fibres as a local supply chain from paddock to end user and back again.

Four years ago, she teamed with innovative Queensland cotton grower, Glenn Rogan of Australian Super Cotton at St George, to build a different model.

Full Circle Fibres is Australia's only paddock to product cotton supply chain although one stage in the process, the spinning, is currently done in the United Kingdom until the $20 million investment in a local mill can be realized.

Innovation consultant Jane Trindall said Meriel has bolted together a cotton supply chain using grit and determination.

"She has shown what is possible in Australia and the region, and we can develop a new innovation economy around that," Jane said.

After growing up in England with 'waste-not want-not' parents, Meriel did a textile science degree followed by jobs working with and learning from older people in manufacturing at a time when quality was valued and ethics were core business, before the race-to-the-bottom of fast fashion that has occurred in the past decade.

Based on this experience, Meriel recognised the opportunity to develop a paddock to product design process for cotton grown in Australia.

Meriel believes Queensland can lead the world with high-quality, ethical and sustainable fibre and yarn production by combining collective knowledge and research intelligence that survives, despite the fact Australia is not considered a manufacturing economy.

"The desire for known, traceable and ethical supply chains for primary product is outstripping available demand. The market is there for sustainable fabric, and building industry capability to fill that need would be source of national pride."

People actively look for Australian food because of its known quality, safety and sustainability. In the same way, the field is wide open for Australia to become known for its material products, rather than just raw resources.

Australia produces only 4 per cent of the world's cotton and currently almost all is exported from Australia as a bulk commodity, sought-after for its high quality and staple length to blend with lesser quality cotton from other regions. Commodity-based trading is intrinsically opaque at a time when customers are seeking more transparency.

People want to know where stuff comes from. Meriel points to farmers markets and the revival of small local producers to whom we can feel a connection and know their story, have a sense of place and feel proud of what we collectively produce.

They want fabulous, ethical, everyday products said Meriel, citing the Full Circle cotton Indigenous weave throw as an example of a collaborative business model. Other Australian clients include fashion labels Citizen Wolf, Alice Sutton's Edition, and Farm to Hanger, with more and larger partnerships to come.

"This is an integrated supply chain, whereas most traditional businesses buy and sell at each stage in the process," Meriel said.

"We can apply ingenuity to solve the problems around local making and manufacturing. We can contribute to solutions through ethical sourcing and being part of the circular economy. We do less, but we can do it well."

Even the name, Full Circle Fibres, tells a story of Meriel's vision for product stewardship and responsible supply chain management because the business is biologically circular, recycling and upcycling endlessly.

Other elements are a supportive family and an innovative grower with a shared dream to grow supply chains without exploitation or waste.

"This is about people who turn up and care about things enough to create change for good," she said.