Increasing areas of cultivation, requirements for larger machines, legislated emissions targets and a drive to digitise technology are just some of the trends defining the future of machinery.

Subscribe now for unlimited access to all our agricultural news

across the nation

or signup to continue reading

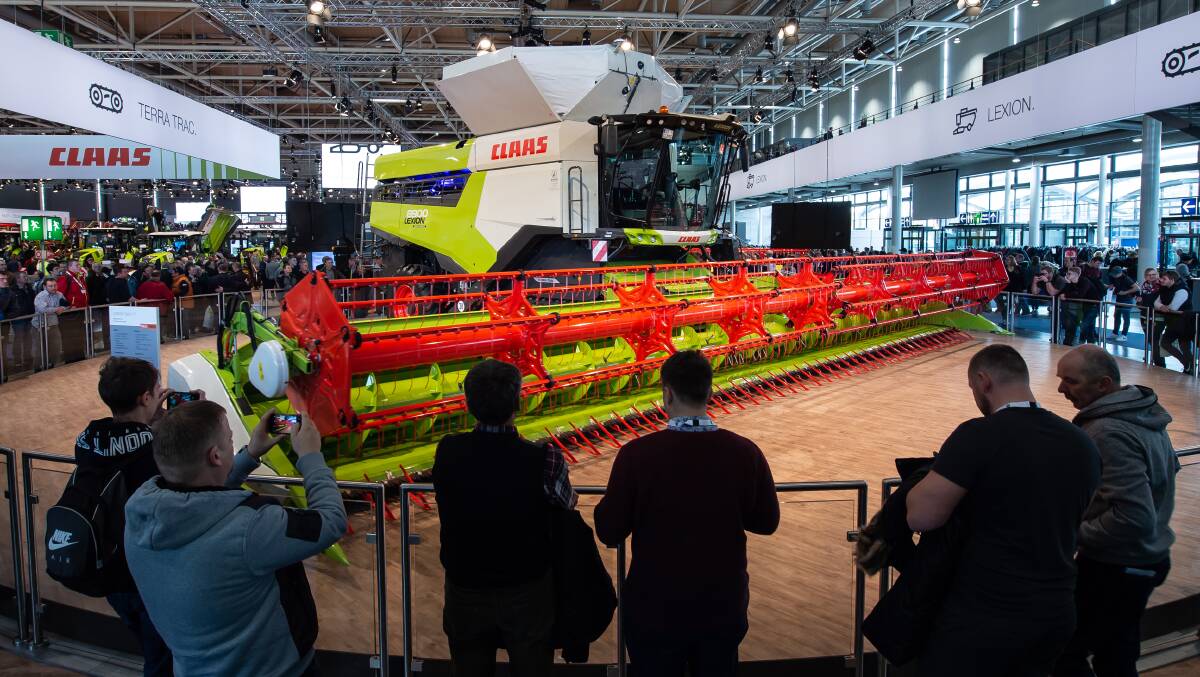

Held in Hanover Germany biennially, Agritechnica, the worlds largest farm machinery trade show, provides a snapshot of current and future trends in farm technology, with over 2800 exhibitors present from across the globe.

Agritechnica Innovation Commission chairman Dr Markus Demmel from the Bavarian State Research Institute for Agriculture said from the machines on display, it was obvious emission legislation was a key driver of tractor technology, defining not only the development of engines but also entire designs.

"An electro-mechanical power-split gearbox that can also supply 100 kilowatt of external electrical power will be presented for the first time in addition to further developed full powershift and hydrostatic-mechanical power-split stepless gearboxes," he said.

"Fully electric concepts with batteries are still being taken into consideration for smaller models."

Dr Demmel said tracked-tractors remained on trend, driven by the requirement for increased traction and reducing soil compaction.

"In addition to the full or semi-caterpillar drives available as standard, one manufacturer is now also offering four factory fitted, fully-integrated triangular semi-tracked drives for standard tractors; these were previously only available as retrofit solutions," he said.

"The range of new and improved offers concerning digital solutions for tractor operation is also very extensive; these are intended to make operation easier and safer and to optimise farm management."

Cultivation on the rise

Dr Demmel said the challenges facing soil cultivation technology were high, particularly in Europe where a decline in available active ingredients used for crop protection was trending.

"In the future, all options for preventing soil degradation, humus loss, diseases and pests will have to be exploited," he said.

"Post-harvest management and soil cultivation play a central role in this.

An increase in operations involving a disc harrow or cultivator is to be anticipated, leading to the extensive decimation of the degree of surface coverage

- Dr Markus Demmel

"An increase in operations involving a disc harrow or cultivator is to be anticipated, leading to the extensive decimation of the degree of surface coverage.

"The industry is called upon to develop tools and implements which lead to the effective removal of weeds and volunteer grain on one hand whilst simultaneously preserving the degree of coverage and the humus content on the other hand."

Dr Demmel said electronics were gradually making their way into sowing and soil cultivation implements, enabling better communication between the tractor and implement and making operation easier and more precise.

"Improved sensor technology, electric drives and the accompanying electronics have considerably increased the complexity of machines," he said.

"The requirements for sowing technology have generally become more demanding, changing row widths, grain singling, simultaneous working in of fertiliser, grain counting sensors and the integrability in the tractor and information system are just a few keywords in this context.

Today the most current goals are certainly the conservation of soil moisture, the improvement of nutrient availability and simplified operability via digital-electronic aids.

- Dr Markus Demmel

"Today the most current goals are certainly the conservation of soil moisture, the improvement of nutrient availability and simplified operability via digital-electronic aids. Current technology offers a broad range of possibilities for achieving these goals."

Precision fertiliser

Dr Demmel said precision fertiliser application technology was moving ahead at a rapid pace, with a particular reliance on digital technologies to improve coverage in variable conditions.

"In the past, when fertiliser mixtures were applied with broadcasters, farmers had no aids for the optimum adjustment of the fertiliser spreader at their disposal.

"With a new app, the expected spreading quality of fertiliser mixtures can already be estimated in advance and for the first time the farmer is provided with adjustment recommendations for the centrifugal spreader.

"Today the advances in control and regulating technology in conjunction with high-performance data networks also enable the influence of the slope inclination to be taken into account during spreading with broadcasters.

"Newly designed and electrically driven metering units enable single nozzle control of the application quantity on pneumatic boom spreaders."

Increased irrigation

Dr Demmel said irrigation is becoming ever more important to safeguard agricultural yields.

"The economically justified use of irrigation is increasing along with the number of dry spells," he said.

"It is therefore to be assumed that, in the medium to long term, irrigation will be extended to further cultures and areas. The fundamental trend towards continuously minimising water consumption is taking this development into account."

Dr Demmel said digitisation and networking sensors have led to the development of more efficient irrigation systems.

The economically justified use of irrigation is increasing along with the number of dry spells

- Dr Markus Demmel

"Increasing digitisation and the possibility of networking sensors have led to the development of new options," he said.

"Individual sensors, for example, rain sensors, can be incorporated in the internet of things, enabling optimised water balancing. The trend in this development is also shifting towards sub-area-specific irrigation , precision irrigation.

"A further trend towards the reduction of operating water pressures and thus the reduction of energy requirements during irrigation can be seen."

Protecting the crop

Dr Demmel said crop protection technologies were focused on increased application accuracy.

"Due to the growing size of farms, the increase in performance continue to have a high priority when purchasing new crop protection implements," he said.

"In line with this trend and due to the fact that crop protection must take place on schedule, there is a growing demand for larger barrel volumes for pulled sprayers.

"Across all spraying systems, one trend is obvious: the capacity utilisation of the sprayer can and must be increased further."

Dr Demmel said the development of diagnosis and forecasting models which integrated with operation and control of equipment would continue to drive crop protection technology in the future.

Tthe combination of mechanical weed control and belt spraying technology offers a huge potential for reducing the amount of crop protection agents used

- Dr Markus Demmel

"Furthermore, the combination of mechanical weed control and belt spraying technology offers a huge potential for reducing the amount of crop protection agents used, improved resistance management," he said.

"Through the use of electronic aids, and in particular by using automatic row guidance, mechanical weed control is provided with the possibility to increase the area output and the work quality, making it competitive once again."

Harvest efficiency

Dr Demmel said there was continued innovation in the development of harvesting technology.

"The world-wide trend to belt cutting systems and techniques for the adaptation of harvesting headers to a broad range of conditions is continuing," he said.

"The belt cutting systems of international manufacturers will also be adapted to European harvest conditions.

"Sensor technology in the blade drive not only enables early detection of damage on the cutter bar, but also for the first time the load-dependent control of the cutting frequency."

Dr Demmel said threshing output continued to rise.

"The threshing and separating elements are designed so that the flow of harvested crops is as linear as possible in tangential threshing units, and is therefore gentle to materials and saves power.

"Not only increased threshing drum diameters, but rather appropriate suitable threshing drum, feed and separating drum configurations contribute to the increased performance.

"Threshing and separating baskets can now be removed and installed from the side for the first time.

Threshing and separating baskets can now be removed and installed from the side for the first time

- Dr Markus Demmel

"On axial rotor combine harvesters, the performance stability is increased with high straw yields and moisture contents through new rotor-housing configurations and modified spreading cylinder-separating basket combinations."

Dr Demmel said top harvester models were equipped with engine outputs of just under 600 kilowatts (800 horsepower).

"This clearly confirms the trend to an increasing power density of combine harvesters," he said.

Dr Demmel said this trend was also apparent in forage harvesters, with further increases to machine outputs and dimensions, along with a focus on efficiency.

"Development work in the square baler segment is currently focusing on improving starting behaviour, for instance, while reinforced bearing, pinion and chain designs are a matter of course for high baling densities in round balers," he said.

"Swathe technology is also undergoing interesting developments aimed at laying the feed in swaths as cleanly and with as little loss as possible.

Digital technology

Dr Demmel said trends towards the use of digital systems in farm management continued, with over 70 new products in this area on display at Agritechnica.

"Interesting new and further developments can be found in the area of farm management information systems," he said.

"With newly structured data platforms, sensors and information that can be linked to each other across manufacturers, and instructions and documentation can be created automatically with them.

"Other interesting further developments can be seen, from intelligent, non-invasive soil sensors to automated weather stations with a multi-sensory approach and crop protection recommendations to remote detection via satellite systems."

Dr Demmel said a range of digital innovations were also being incorporated into the cabin.

"The use of holographic elements in the driver's cab and augmented reality and goes all the way up to freely configurable multi-terminal systems," he said.

"Automatic overloading systems with artificial intelligence and radar-supported warning systems for people in the area around agricultural machines also serve to reduce the strain on drivers and are intended to decrease the frequency of accidents."