THE push to better quantify what is in a beef or lamb carcase in terms of both the amount of cuts and the eating quality of the meat is moving at a solid pace.

Subscribe now for unlimited access to all our agricultural news

across the nation

or signup to continue reading

Objective measurement technologies are proving accurate, repeatable and robust but at the same time, those at the forefront of driving the new era both inside the processing plant and from a scientific perspective have their eye firmly on the quality side of the equation.

Will Barton, the chief executive of Gundagai Meat Processors, a family-owned lamb abattoir that has lead the way to install and trial technologies like Dual Energy X-Ray Absorptiometry, believes a 'lamb revolution' is on the way.

At a recent webinar organised by the Australian Intercollegiate Meat Judging Association, he spoke about how the red meat industry would ease its way into value based marketing as the new carcase measurement technologies came into play. He emphasised the need to ensure pricing signals for eating quality happened at the same time.

Mr Barton touched on the heights lamb prices have reached, saying the industry was now in a "counter intuitive situation where prices are following caviar but the product is becoming more like a chicken breast with flavour and fat bred out."

"So we have a confused lamb category which on one hand is developing itself to be more efficient in production with higher lean meat yields and higher weights, but is still trying to hang onto a premium for a product which has different attributes," Mr Barton said.

Big changes in attitudes around genetics would come quickly once the technology for objectively measuring attributes was in play - and that's why it would be a revolution, rather than an evolution, he said.

GMP's innovation and technology rollout began four years ago and the total project spend has been circa $2.4m, of which $900,000 or 37 per cent was funded by Meat & Livestock Australia.

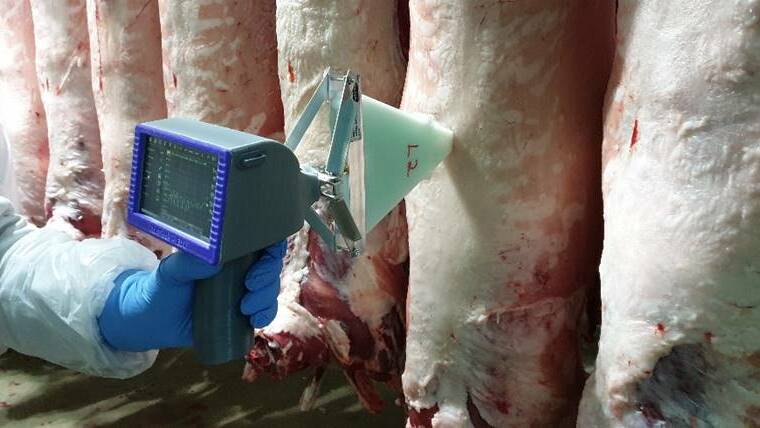

The plant was the first in the world to install DEXA on a slaughter floor, or 'hot side'.

There had been big internal challenges around meeting production requirements and getting the technology up and running, Mr Barton said.

He outlined four new pathways his family's operation was taking in relation to OCM and value based marketing.

They are: DEXA, which measures lean meat yield, fat and bone percentages; the monitoring of significant animal health conditions; intramuscular fat measurement which is key to eating quality in lamb and the concept of carcase optimisation.

GMP hoped to be able to provide suppliers with data on an individual carcase basis around lean meat yield, carcase weight and disease data very soon.

The right tools

Mr Barton said to turn all the data coming from the new technologies into success for a red meat business, the right tools to interpret it was needed - that is someone internally able to make the data meaningful.

To that end, GMP appointed meat scientist Dr Michelle Henry to a newly-created role of client research advisor to provide technical advice to clients.

"The second thing is infrastructure - it's all well and good to have all the answers about carcases but the ability to execute that into results throughout the plant requires infrastructure," Mr Barton said.

GMP has invested a large amount in the past three years in an advanced carcase chilling and sortation system.

"Actioning the intelligence allows us to pay farmers in a targeted fashion for the quality and yield they are producing," Mr Barton said.

"It also allows us to command more from consumers because they understand what they are getting and there are guarantees around it.

"It's the four of those things in combination which we believe can dramatically change the landscape for the lamb industry - but we must have the patience to wait for the IMF technology."

Leading meat science researcher, Associate Professor Graham Gardner, from Western Australia's Murdoch University, agrees.

Prof Gardner is head of the national research project looking at advanced livestock measurement technologies, known as ALMTech.

Eating quality was not such a big issue in beef because Meat Standards Australia provided a corresponding signal but the lamb industry was not yet measuring it, he said.

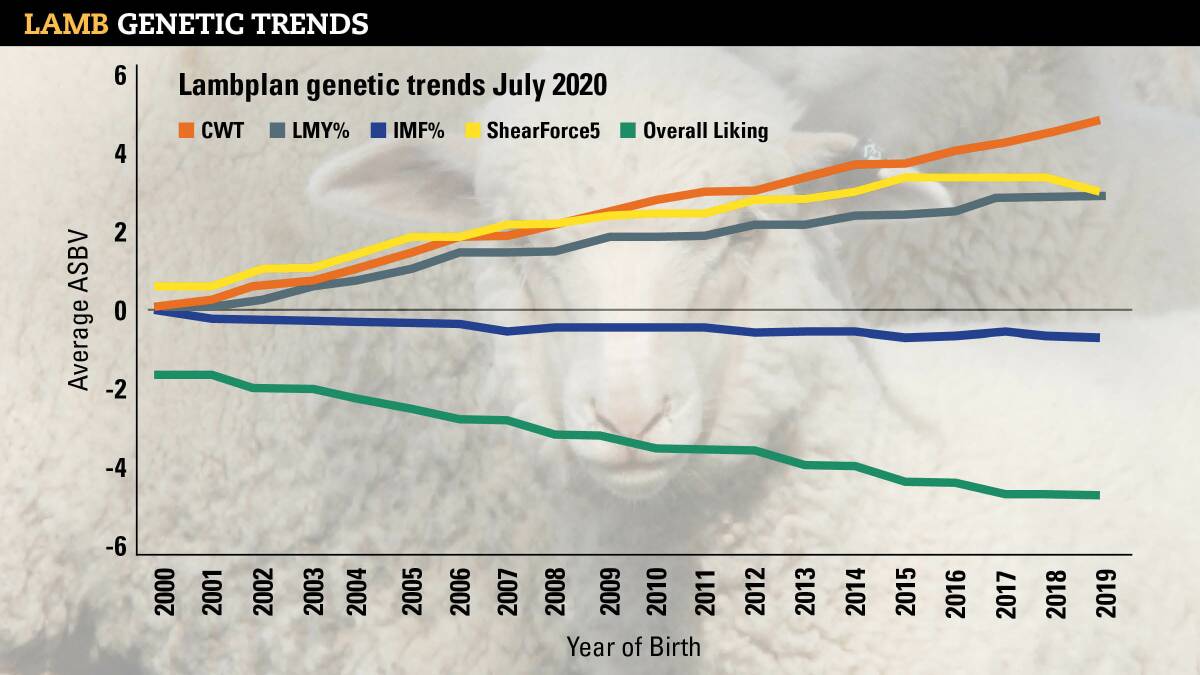

Prof Gardner presented a graph of lamb genetic trends, which shows traits like carcase weight and lean meat yield have been tracking up over time, but traits like IMF and 'overall liking' - a consumer satisfaction measure - were going down.

IMF accounts for around 30pc of variation in eating quality in lamb - much more than it does in in beef.

"It is crucial to get the two signals - lean meat yield and eating quality - out simultaneously so industry can respond," he said.

Eating quality was a continuum across age, the older a lamb the poorer the eating quality, Prof Gardner said.

"If we rolled out an MSA system in lamb equivalent to beef we'd be in business," he said.

"The industry won't do away with hogget and mutton categories anytime soon but we could categorise the eating quality within those carcases and then let supply chains underpin brands with far better precision, using that information."

The yield benefit

Prof Gardner told the webinar lean meat yield was worth big bucks when the extra value collected on the retail sale of a carcase was filtered back through the supply chain.

He provided an example of the value difference between two lamb carcases of the same weight. One with a fat score of 4 had a saleable meat yield of 48pc; the other with a fat score of 2 had a saleable meat yield of 56pc. The first sold at retail for $144 compared to second at $173.

While retail values might change, Prof Gardner said that type of differential existed every time.

"Carcases are traded on weight but also on the fatness of the carcase, applied as penalties - rib fat depth and P8 fat depth in beef, for example," he said.

Existing industry measures in this space don't work well, Prof Gardner said.

Thus the drive to establish advanced livestock measurement technologies.

Optimising value

The ALMTech work is trying to develop carcase measurements for lean meat yield in both the abattoir and in the live animal.

Lamb DEXA has been a key focus. It originally kicked off in 2012 with a robot cutting lamb carcases into three parts.

The early work focussed around adapting the existing 2D x-ray hardware that was driving that system to convert it into a DEXA image.

Trials at the JBS Bordertown plant have shown DEXA performs well in predicting yields. Five systems are expected to be installed across Australia by the end of this year.

"We have to be able to ensure if we take the same carcase to two different abattoirs we'll get the same answer," Prof Gardner said.

JBS cross-site calibration has already demonstrated alignment in values, which is providing strong confidence for the technology.

Research is also showing carcase scans don't change with time.

DEXA technology can also predict cut weights. In studies, 160 different parts were weighed after boning out and DEXA predictions were extremely accurate.

"The ability to measure carcases in great detail, estimate their cut weights and know their retail values means processors can work out how best to cut up carcases," Prof Gardner said.

"If you can optimise how you target carcases to the different markets out there, you are optimising the value you extract."

Gold standard

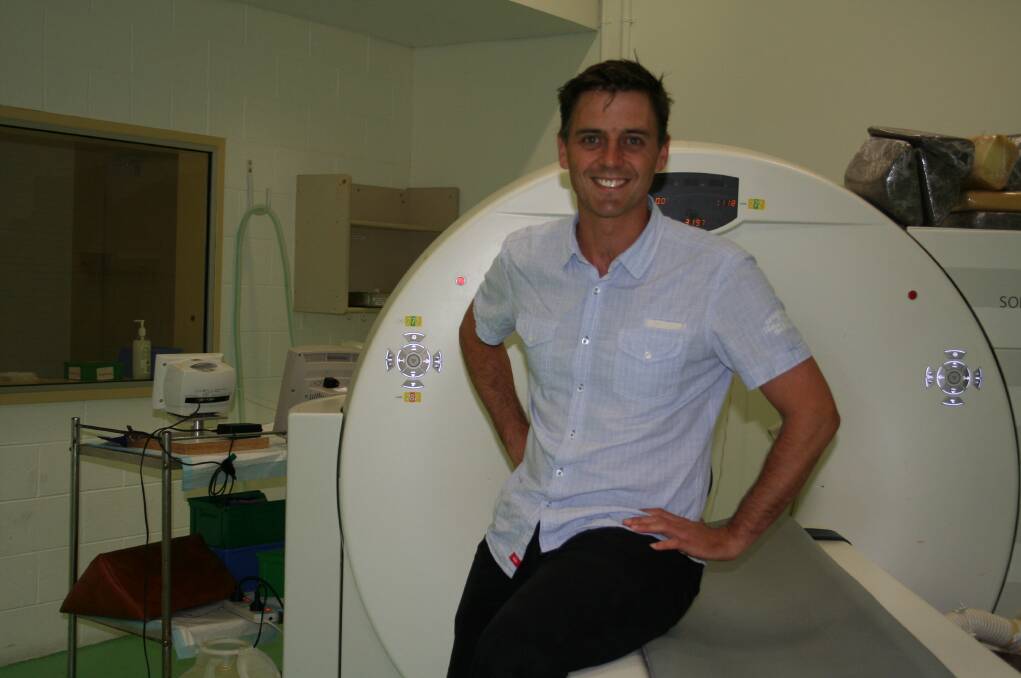

Computerised tomography, or CT, scanning is being used as the gold standard trait for measuring lean meat yield, so as additional technologies are brought in alongside DEXA, consistency is guaranteed.

Other yield assessment technologies in the pipeline include 3D surface imaging, with work underway to install the first prototypes in Australia.

Frontmatic BCC-3 cameras, which capture multiple images of a carcase, E+V carcase scanning systems and VIAScan are three being explored in collaboration with various companies, which Prof Gardner said look promising.

Tissue depth technologies - handheld units that emit microwaves to measure fat depth- are also performing reasonably well.

"These technologies are cheaper and portable, so offer potential advantages for a small processor," Prof Gardner said.

"We are also having a go at measuring tissue depth and carcase composition in live animals with this."

Prof Gardner said carcase composition information was already being communicated back through the supply chain to both farmers and geneticists.

"Lean meat yield percentage breeding values - which are CT compositions - are in place with Sheep Genetics and Livestock Datalink, MLA's system of providing abattoir information back to producers, has a LMY trait," he said.

Look out for our special publication Carcase Merit in The Land, Queensland Country Life and Stock and Land this Thursday.