Some dairy farmers are now using activity meters to assist with breeding and managing their cows. What are their experiences and what tips and traps can they share?

Subscribe now for unlimited access to all our agricultural news

across the nation

or signup to continue reading

In the past 12 months TechKISS project has been exploring these questions with NSW farmers. The aim is to identify the things that lead to successful decisions and implementation, without a commercial bias.

The project started with a survey of all NSW farms and followed up with more detailed information from visits and input from 39 farmers.

These case study farms have provided a wealth of wisdom for others considering purchase or looking to get the best from the tech they are using.

Activity meters in Australia

There are currently 16 different products on the market in Australia. Some of them are essentially the same piece of technology under different brand names.

By far the most common are collars, but activity meters in ear tags, leg tags and a rumen bolus are also available.

The early activity meters were simple step counters, but in the past five years these have been superseded by new position-detecting technology (equivalent to the tech used in smart phones).

In addition to detecting movement, some devices measure rumination, temperature and/or respiratory rate and incorporate this in their fertility and health calculations. Including more of these elements can improve the accuracy of the algorithms to pick cows on heat, and provide alerts for different types of disease and stress.

These may be optional features which farmers can have 'switched on' when the product is purchased.

Activity meters store data over blocks of time (varies between 15 minutes to two hours) and transmit it at a set radio frequency when they come into range of an antenna. The original activity meters were only read when cows came to the dairy, but current activity meters can be read over longer distances (varies from 100 metres to one kilometre).

Some products upload to a local computer and some send data directly to the cloud.

Like all tech, the widget is only part of the story the software that runs it and interprets and displays the data is just as important. The more data available, the better that the software can be optimised, so there have been lots of updates to improve reliability in Australian conditions. These updates are usually done remotely by the developer.

Some activity meters share their data with other technology (such as drafting gates, herd management software) and some don't. This is an important feature to think about when considering a purchase. If activity meters are compatible with other technology on the farm, it avoids the need for double entry of data.

How many farms are using activity meters?

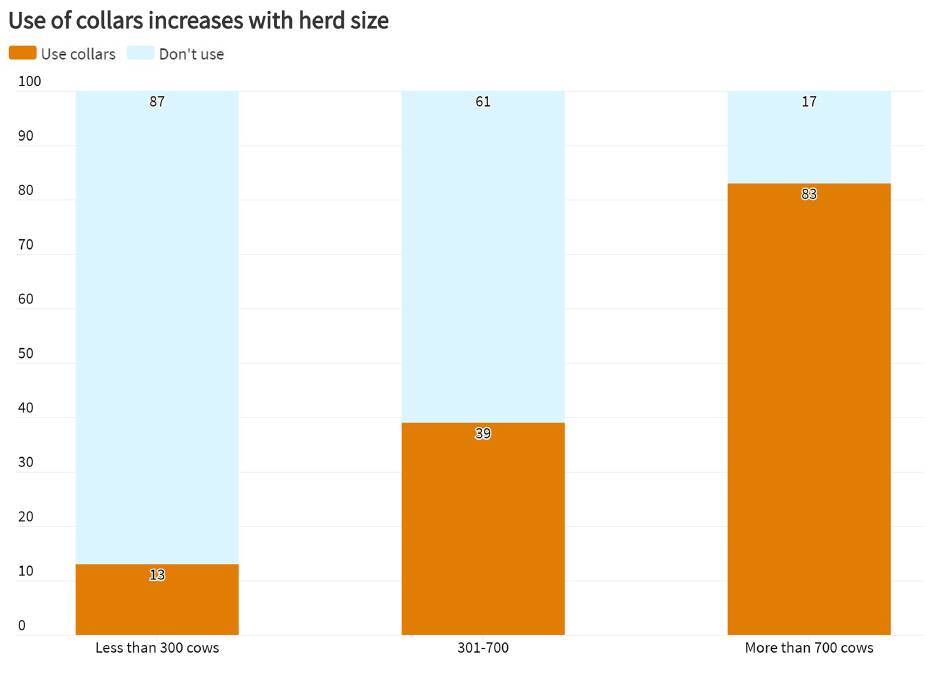

In 2018 activity meters were used on 26 per cent farms in NSW, particularly the larger farms (see graph).

Virtually all are collars, with a few farms also using ear tags. Some 61pc were purchased in the past two years; 72pc are measuring rumination.

In NSW (in year-round calving systems) collars are primarily being used for heat detection and sick cow alerts.

The case study farmers said their main fertility-related benefits from using collars were:

- Achieving improvement in labour efficiency, for example, replacing tail painting and observation.

- Finding cows that wouldn't have been picked on heat especially when less experienced staff were involved.

- Replacing the need for synchrony programs and reducing prostaglandin use.

- Reducing the number of bulls running with the herd (as a workplace health and safety issue).

- Generating vet-check lists (eg non-cyclers and cows with short returns).

- Generating pregnancy test lists.

- Picking up early abortions.

- Better timing of insemination and increased confidence in using sexed semen.

Overall, farmers are highly satisfied with activity meters. Some 90pc of farmers using collars in NSW said they had made a significant contribution to their farm business. Some 20pc said the collars were not "doing everything we want them to". These were mostly older-style collars purchased more than five years ago.

Advice to other farmers

Those involved in the project provided some tips to farmers thinking about using it.

Firstly, think about the likely pay-back period for the investment. The costs typically range from $150-$250 per collar depending on what's switched on (ear tags are cheaper) and $5 to $15,000 for associated hardware and set-up. Likely returns will depend on what the farmer wants the activity meters to do and how much improvement/efficiency they can offer in a herd. Tips/traps: Every farm is different "for us the big value was having a way to get off farm".

Before buying, decide the amount of integration with other tech that is wanted. Will the products under consideration synch with the drafting gates and herd management software on the farm? Does this matter some farms don't mind (too much) about multiple entry of cow data, others hate it. Activity meters that integrate with herd management software will automatically harvest data for herd level reports and actions. Tips/traps: "don't buy on a promise" the farmer has to be comfortable with the capacity for data synching that is available at the time that they purchase. More data integration may happen later, but it might not. If it's essential, make it a condition of purchase.

Decide where the information needs to be able to be seen and who will use it. Will the information be displayed where it is needed, for example on a phone app, at the dairy, where cows are examined or just in the farm office? Will staff be able to see it? Is it easy to read? Tips/traps: "Workers will need to see and understand the outputs if you want them to use them".

Consider the level of support needed. What is the warranty? Is there a product plan that includes technical backup? Most of the software support can be done quickly by remote access if the supplier or distributor provides that service. Tips/traps: Check that repairs to the system can be done quickly (within 1-2 days) if relying on activity meters for heat detection.

Work with the person installing the gear to get the best signal coverage. The locations of the base and antennae are important. Topography of the farm makes a difference, with hills more of a challenge. Repeaters can be set up to extend the distance that signals can be read so there is more timely information and groups of cows or heifers that are not coming to the dairy can still be monitored. Expect to do some adjustments to get it right. For example some other equipment, especially bluetooth devices, can interfere with function. Tips/traps: Extraneous signals can occur from collars that are not in use store transponders in a metal cupboard to avoid this.

Decide whether or not collars will be moved between cows. Some farms choose to put a collar on each cow and leave it on. Others swap collars from in-calf cows to fresh cows. Shifting collars reduces the total number to purchase but adds to workload and means the opportunity for information about the cow in the time it is not wearing a collar is lost. Tips/traps: each cow needs to wear a collar for 7-10 days for its data generated to be reliable, so ensure there is enough time between fitting a collar and wanting to use it.

Have good facilities and a specific protocol for fitting (and removing) collars. Cows are strong in the neck and heads are hard. Collars need fitting at the correct location and tightness. Tips/traps: "Someone's hand getting broken is a real WH&S risk if you don't make sure staff get the process right and stick to it".

Related reading:

Be prepared to spend a few weeks getting used to the new system then shift over. Most farms find they keep on doing their usual heat detection for a few weeks to become comfortable with the new system and confident that the activity meters are picking up the cows they see on heat.Tips/traps: "Don't get into the trap of keeping your old heat detection system going once you can see that the collars are working keep an eye out, but trust them". And always keep a good visual ID system.

The TechKISS project is supported by the NSW Dairy Industry Fund. For more info contact Pauline Brightling or 0418 336 211.

This story first appeared on Australian Dairyfarmer